THE PROBLEM

The leaking buried Polypipe Ridgistorm tank was saturating the surrounding soil through the join in its construction. Others had tried to resolved this previously without success.

SOLUTION

Because of the tanks construction from High density polyethylene which is a notoriously difficult substrate to adhere to this tank relining project was a particularly difficult technical challenge. Also the split along the join raised concerns about the potential for future movement which could split the new tank lining.

To overcome both of these issues we proposed the application of SPI Corrolastic HT – a high tensile polyurea tank lining which effectively forms a ‘tank within a tank’.

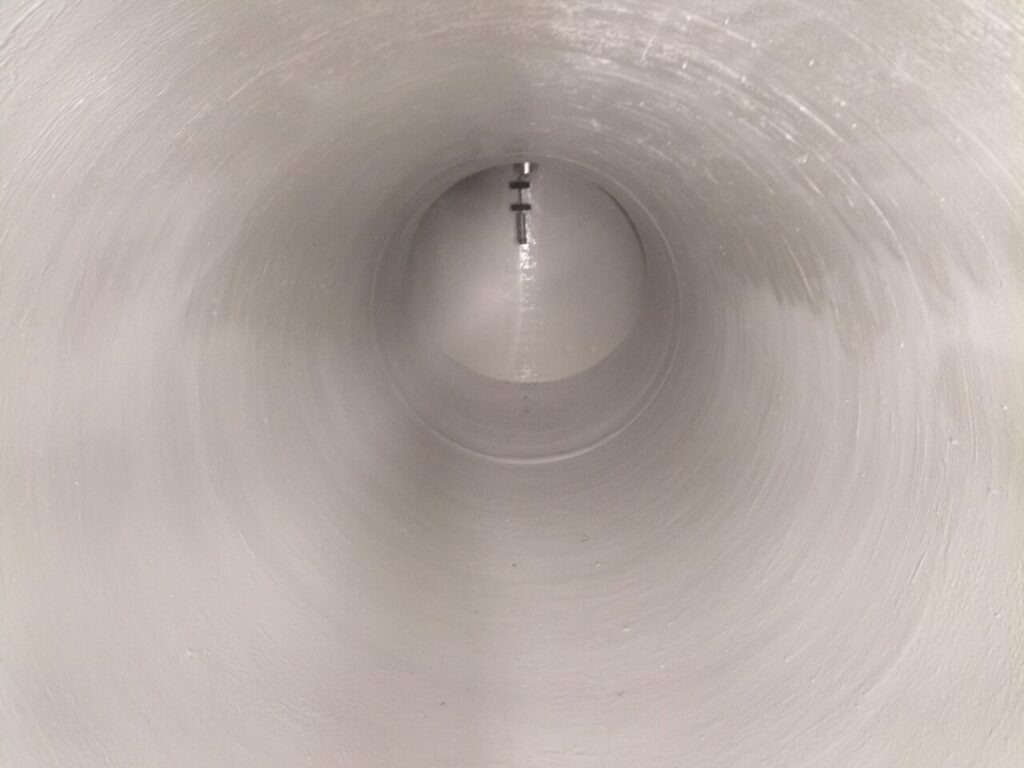

The first stage of the tank relining process was to thoroughly abrade the tank internals to provide a key for the new tank lining to adhere to. All surfaces were then thoroughly cleaned by high pressure washing to ensure the best possible surface for tank lining to adhere to.

All surfaces were then coated using Corrolastic SG – one of the few products that will adhere to HDPE and LDPE. In the are of the tank join this was reinforced with a bandage detail for additional strength.

Following hydration of Corrolastic SG dehumidification was introduced to ensure the correct climatic conditions for coating application.

All surfaces were then primed using a damp tolerant epoxy primer applied at 0.3Kg/m2 to fully seal the surface and minimise pin holing in the polyurea tank lining.

Finally SPI Corrolastic HT was applied using our plural spray equipment to a thickness of 2mm. This was the perfect tank relining solution for this challenging application as the material can elongate over 400%, meaning that potential movement should be accommodated without splitting the tank lining.

This tank relining material also has an expected design life of 30 years from completion providing a long term lining solution.

We were not able to spark test this tank lining due to the non conductive nature of the substrate so a through visual inspection was undertaken. Fortunately the priming regime had effectively sealed the substrate prior to the application of the polyurea tank lining.