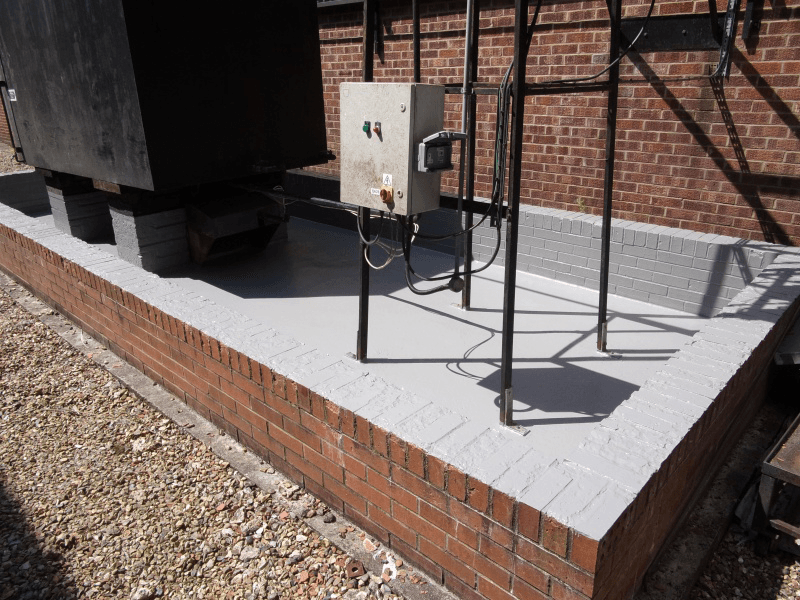

Heating Oil Bund Linings

THE PROBLEM

The heating oil bunds where no longer water tight and if a leak or spill were to take place the local environment would be contaminated. The top course of engineering bricks were also exhibiting significant degradation as a result of frost damage.

THE SOLUTION

We proposed the application of an elastomeric bund lining solution from Sika as recommended by our partners at NCC that would form a seamless secondary containment solution.

Initially the bunds were cleaned using an emulsifying degreaser and a high pressure spinning jet to provide a clean, oil free surface ready to accept a bund lining. This also removed surface laitance and the ares of degraded blocks at the top of the bunds walls.

Once clean the bunds floors were primed using Sikafloor 161 damp tolerant epoxy primer applied by brush and roller. The engineering brick bund walls were primed using Sika Bonding Primer which is a water based epoxy which offers excellent adhesion to dense and hard mineral substrates such as the engineering bricks used in the construction of secondary containment bunds.

Following the priming of the bunds the next stage of the bund lining process was the installation of a fillet detail at the intersection between the bunds floors and walls to isolate this point of potential movement. The fillet was created using Sikaflex Pro 3 polyurethane jointing compound.

Finally once satisfied with the preparation and priming works Sikafloor 400 was applied throughout using brushes and rollers. This elastomeric polyurethane remains fully flexible when cured allowing the accommodation of movement that is often found in secondary containment bunds through thermal expansion and contraction.