THE PROBLEM

Brixton Water treatment works had been offline for several years. As part of the recommissioning works the 8 filter vessels media was being changed. During this process it was discovered that in all of the vessels some degree of lining breakdown had occurred.

As well as the corrosion present it appeared that there was an inter coat adhesion issue as large areas of the top coat were debonding from the coating beneath.

SOLUTION

As requested we quoted for the application of Acothane DW – a regulation 31 approved material for use in the public supply.

In line with the instructions for use all of the existing coatings were removed by method of abrasive blasting, preparing the steel to SA2.5. When applying tank linings used in the public supply it essential that the instructions for use are tightly adhered to in order to ensure the high standards required are achieved.

The existing coating was extremely thick and tough and in some vessels we also employed ultra high pressure water jetting to first remove the existing coating prior to abrasive blasting to achieve the required preparation standard.

The surface profile was checked and recorded using a surface profile needle gauge to ensure excellent adhesion of the new tank linings.

As part of our standard quality assurance the surfaces were checked for soluble salts and dust tape tests conducted following cleaning to ensure cleanliness prior to application of the new tank linings.

As per the instructions for use and tank lining best practice a separate stripe coat was applied to all angles, edges, nuts and bolts. This was not small task given that this had to be completed in one shift to ensure that the recoating window was not exceeded – a common cause of inter coat adhesion issues as witnessed.

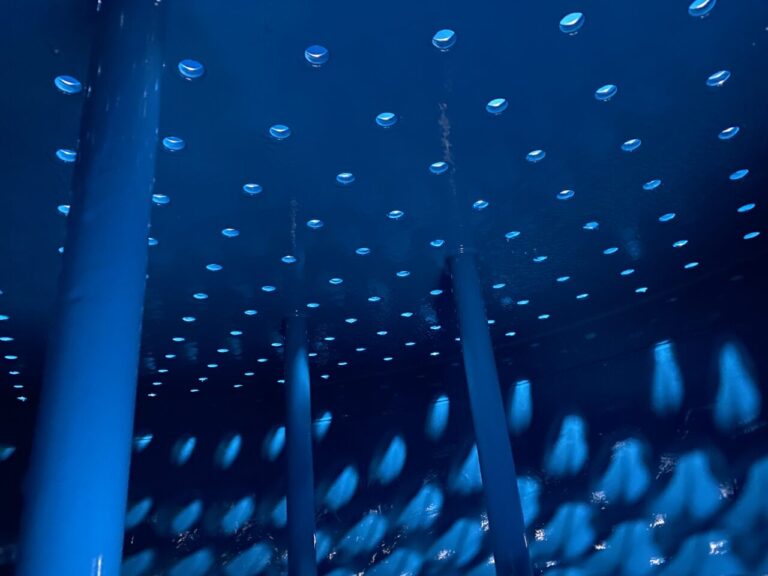

Acothane DW was then applied in two coats by method of plural spray unit to a target thickness of 1000 microns. Each coat was applied in a contrasting colour as per the instructions for use and standard tank lining procedure.

Dry film thickness readings were taken and were required marked prior to rectification. The new tank linings integrity was checked for pin holing using a DC Holiday spark tester.

These works were undertaken during summer months, which presented a challenging working environment as the internal temperatures of the tanks were elevated significantly. The spray application had to be rotated between applicators to avoid fatigue and heat stroke.