THE PROBLEM

The sectional wastewater tank was preventing an environmental risk through perforations in the tank structure allowing sewerage to leak into the surrounding soil. As requested we put together a seamless tank lining proposal that would return the tank to a serviceable condition.

SOLUTION

Following the drain down of the tank, the tank internals were prepared by abrasive blasting to remove the existing glass enamel finish and prepare the steel substrate below to SA2.5 as per the manufacturers recommendations. The blast profile was checked and recorded by our in house ICORR paint inspector and a surface cleanliness test conducted to ensure excellent adhesion of the new tank lining.

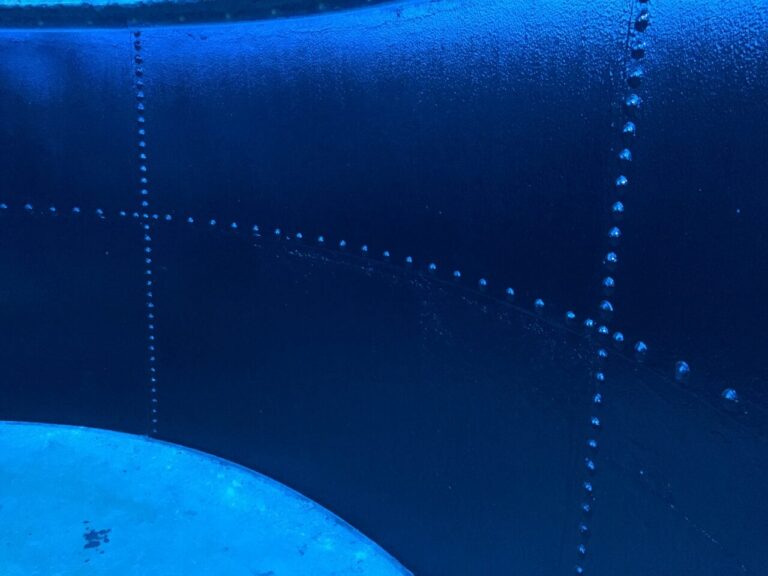

Due to the large number of perforations in the tank structure these areas were reinforced by the inclusion of glass fibre chopped matt in the first coat of Remmers Epoxy Universal to bridge these perforations. At each stage of the coating cycle the numerous nuts and bolts throughout the tank received a separate stripe coat to ensure full coating film build on angles and edges where paint pulls thin.

Finally the tank lining was tested throughout for pin holing using a spark tester, where found these were marked with chalk prior to touching in using the same material.