THE PROBLEM

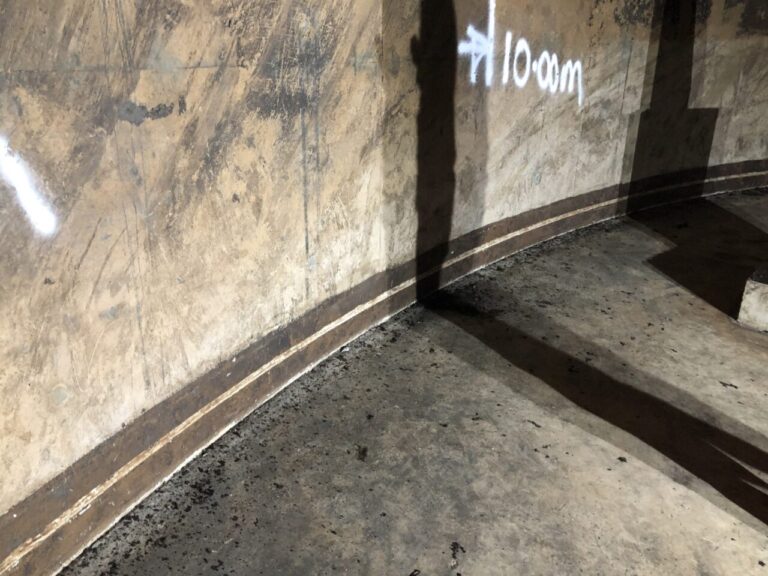

The expansion joint at the base of the anaerobic digester was leaking allowing sewage to leak into the surrounding environment.

SOLUTION

Once the client had drained and cleaned the tank we were able to identify that the cause of the problem was the failure of the existing sealing bandage system – less than 10 years after installation.

Although we could not identify the exact point of failure, a common weakness in these type of bandage systems is that they rely on heat welded joins where they lap – which will always be a point of weakness. Once a point of entry has been made liquids can track behind within the joint space and exit from an entirely different location.

Instead of replacing with the same material we instead proposed the application of a seamless polyurea coating in the form of SPI Corrolastic HT.

Initially the de-bonded central section of the bandage was cut out and the remaining epoxy adhesive and adjoining concrete was prepared by method of vacuum controlled diamond grinding.

To ensure the correct climatic conditions for polyurea coating application indirect oil fired heating and dehumidification was introduced. The moisture content of the concrete was checked and recorded using a Tramex moisture meter to ensure that it was below the 6% required.

Anchor rebates were cut at the perimeter of the area to be coated to provide a ‘toe in’ for the new polyurea coating.

All surfaces were primed using a damp tolerant epoxy primer to ensure excellent adhesion to the substrate. The expansion joint was sealed using backer rod and a flexible polyurethane jointing compound. This would prevent liquid tracking around the expansion joint in the event of damage to the polyurea membrane.

SPI Corrolastic HT was then spray applied to a thickness of 2mm. The benefit of a polyurea coating over conventional bandage systems is that it is completely seamless, with no welds or joints – ensuring a fluid tight seal. SPI Corrolastic HT can elongate over 400% which is equivalent to conventional bandage materials.

The previously cut anchor rebates were then sealed using a polyurethane jointing compound to prevent moisture creeping under the edge of the polyurea membrane as per best practice.

Polyurea coatings have a design life in excess of 30 years when installed correctly, which will comfortably exceed the life span of the previous waterproofing bandage material.