A glass fused to steel effluent tank in Buckinghamshire was experiencing significant leakage due to corrosion and perforations within the gas space. Temporary patch repairs had been attempted previously, but the client required a long-term industrial tank lining solution that would ensure full containment and protect the structure against further degradation.

Glass Fused To Steel Effluent Tank Lining – Buckinghamshire

THE PROBLEM

THE SOLUTION

Corroless Eastern has extensive experience working with glass fused to steel tank lining, supported by dedicated research into how these tank systems respond to coating technologies.

Following inspection, we proposed two options to the client, who selected the more durable polyurea tank lining system — SPI Corrolastic UB. This system offers exceptional durability for wastewater and effluent tank lining applications.

1. Sealant Removal

The first step was the removal of the polyurethane pointing applied during original tank construction. This step is essential to:

- Expose corroded or at-risk areas where breakdown often occurs beneath the sealant.

- Eliminate complex edges and voids that would prevent a seamless coating application.

Specialist Japanese leather knives were used for this process.

2. Cleaning & Soluble Salt Removal

All surfaces were steam cleaned with an emulsifying degreaser to remove fats, greases, and soluble contaminants. Effective soluble salt removal is critical, as remaining salts can lead to osmotic blistering beneath the tank lining.

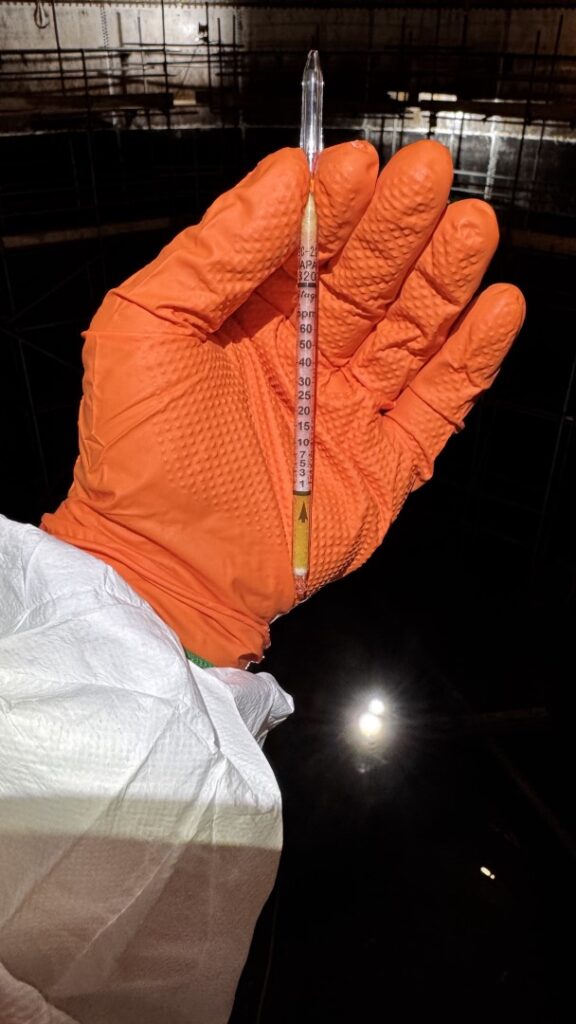

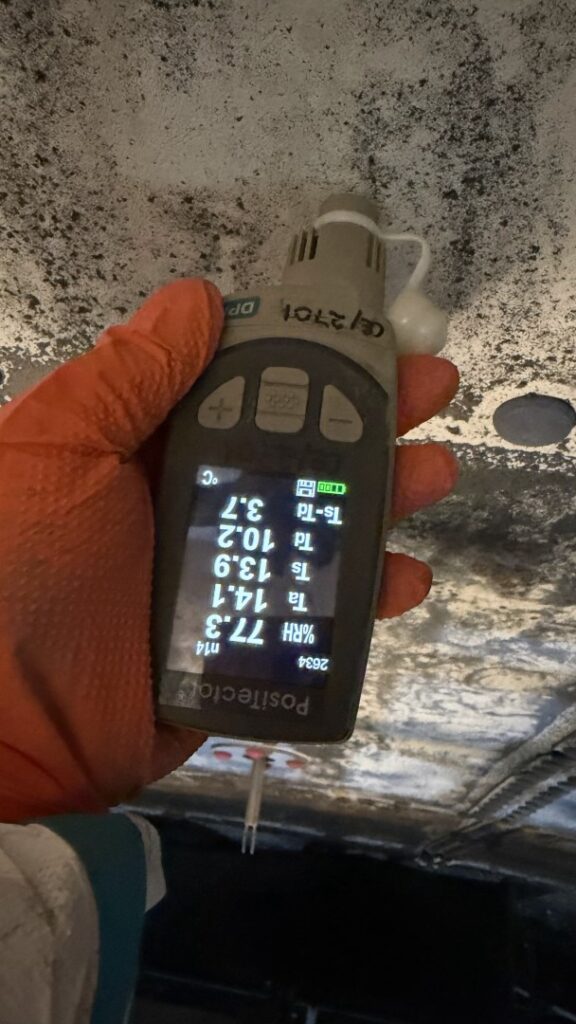

Soluble salt tests were carried out as part of our standard QA procedures

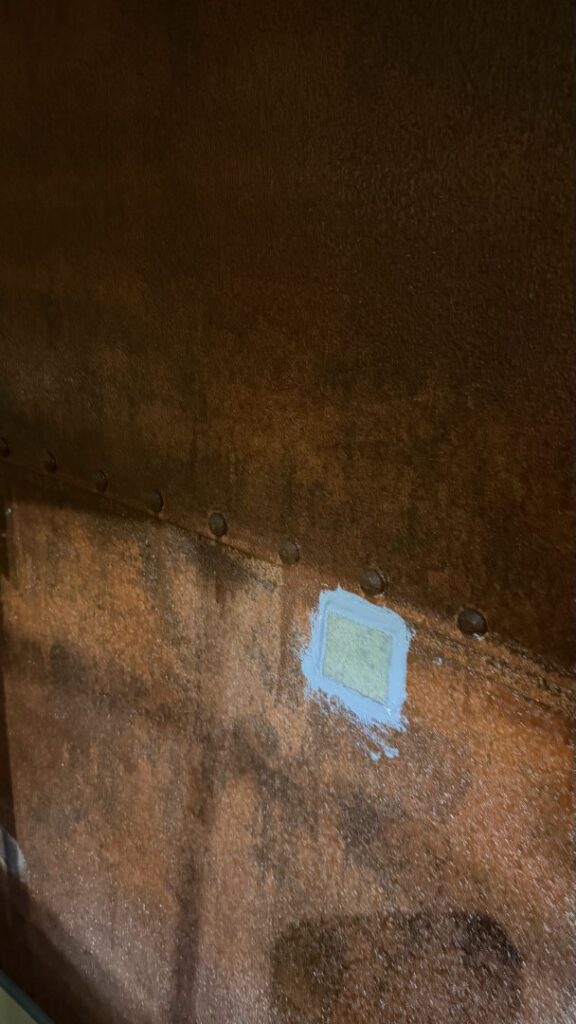

3. Surface Preparation

Adjacent panels not being coated were temporarily protected with rubber sheeting.

The glass enamel was sweep blasted to expose clean, fresh surfaces, and all exposed steel was prepared to SA2.5 abrasive blasting standards in accordance with ISO 8501-1.

Surface roughness was recorded using a profile needle gauge.

4. Priming & Mechanical Profiling

The prepared surfaces were primed using our specialist Corrolast DSP primer, designed for superior adhesion to glass enamel and steel substrates while providing enhanced anti-corrosive protection.

A quartz broadcast mechanical profile was applied into the wet primer to create an optimal bonding surface for the spray-applied polyurea lining.

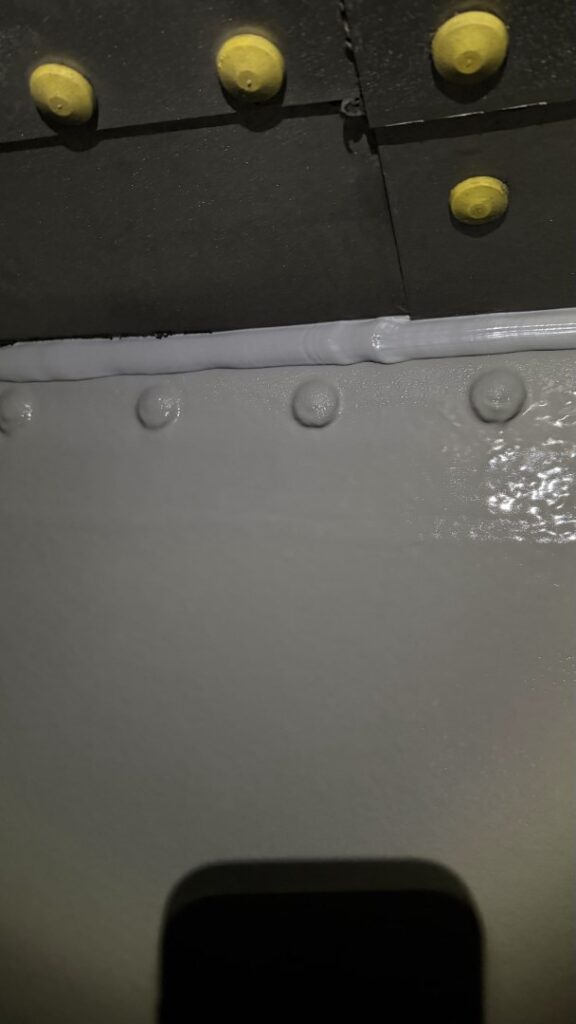

Perforated sections of the tank were bridged using galvanised steel plates bonded with a thixotropic epoxy adhesive.

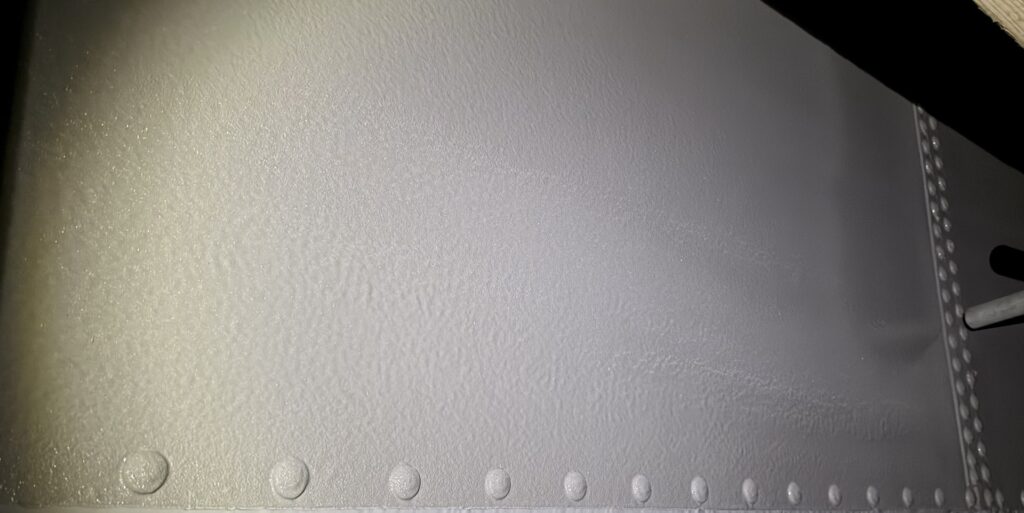

5. Polyurea Tank Lining Application

Areas not to be coated were masked using specialist cutting tapes, suitable for the rapid gel time of polyurea systems.

Our trailer-mounted unit was mobilised to site, and SPI Corrolastic UB was spray-applied to a nominal thickness of 2mm across all prepared surfaces.

6. Quality Assurance & Final Protection

The cured lining was tested using a DC holiday spark tester to identify and address any pinholes, ensuring full continuity of protection — crucial for tank corrosion repair in aggressive waste water environments.

All termination points were then sealed using a chemical-resistant polyurethane sealant to ensure a fully encapsulated and durable finish.