THE PROBLEM

The original protective coating on the tank internals had failed, resulting in a heavily corroded substrate. The rough, pitted and unhygienic surface this provided would support the growth of aquatic micro organisms such as Legionella, presenting a health risk to users of water stored within the tank. Furthermore if the Corrosion present were allowed to develop it would lead to pin holing and the eventual failure of the tank lining.

SOLUTION

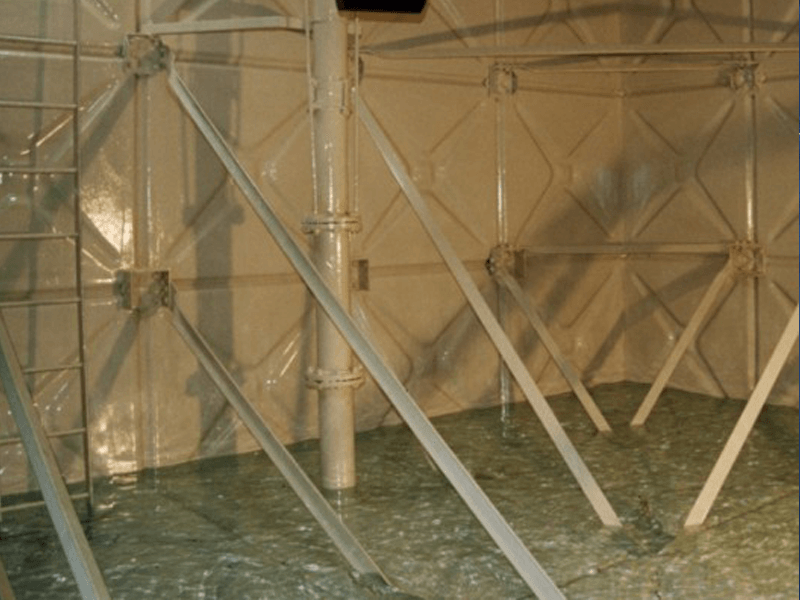

The tank substrate was manually and mechanically prepared using chipping hammers, tungsten carbide scrapers and needle guns to remove all laminate and loose/unsound corrosion present to achieve Swedish surface preparation standard ST2. A heavy stripe coat of Corroless EPF rust stabilising epoxy primer was applied to all angles, edges, welds nuts and bolts to ensure a full film thickness.

Two coats of Corroless EPF were then applied throughout the tank in contrasting colours (any misses are easily spotted) to a dry film thickness of 400 microns. Finally a coat of Corroless RF35 glass flake reinforced epoxy resin was applied throughout the tank to provide a dense impermeable hygienic finish, giving a system thickness of 600 microns.

Corroless EPF is specifically formulated to stabilise corrosion in damp aggressive environments following minimal surface preparation, obviating the need for costly and disruptive abrasive blasting. Corroless EPF and RF35 both contain self leafing glass flake which laminates at the coating surface forming an impermeable barrier to chemicals, moisture and oxygen.

Because of the extremely smooth, hygienic surface formed as a result of this laminating glass flake, the Corroless EPF/RF35 tank lining system will not support the growth of aquatic micro organisms such as Legionella. This system is approved by NATO for use in submarines and warships