Anti-Corrosion Protective Roof Coating

THE PROBLEM

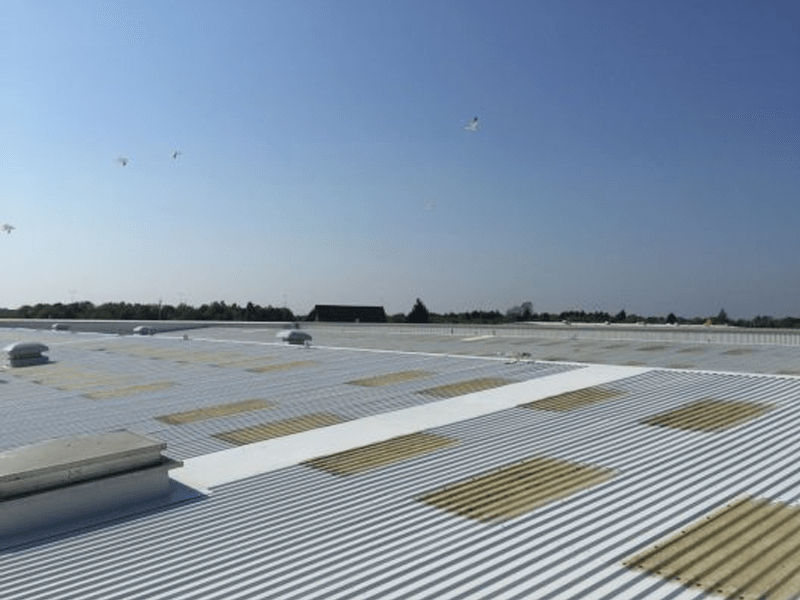

The warehouse roof was showing signs of corrosion as well as being covered in organic growth and needing remedial works as part of plans to put the warehouse back into use, under new ownership.

THE SOLUTION

We recommended the application of a water based, elastomeric, rust preventative coating to provide a long term protective coating solution.

Initially the roof and skylights were prepared by method of high pressure water jetting (5000psi) to remove dirt, organic growth and any flaking and/or unsound areas of coating, prior to the protective coating application process.

A heavy stripe coat of Rustoleum Noxyde was then brush applied to all joins, edges, angles and bolts. Stripe coating is a vital stage of any protective coating application cycle, and ensures full coating thickness is achieved.

A full coat of Rustoleum Noxyde was spray applied to all areas of cut-edge corrosion, prior to the whole roof receiving a final coat of Rustoleum Noxyde again by airless spray.

Care was taken to leave a precise finish of the protective coating system around the multiple fibreglass skylights, as following the cleaning and preparation stage the lights let in approximately 70% more light than previously, subsequently flooding natural light into the building below.

The project was completed in good time, with only weather causing minor delays during the coating process.

The job was handed over to a happy and satisfied client, with a ten year warranty and expected service life in excess of this.