Water tank relining

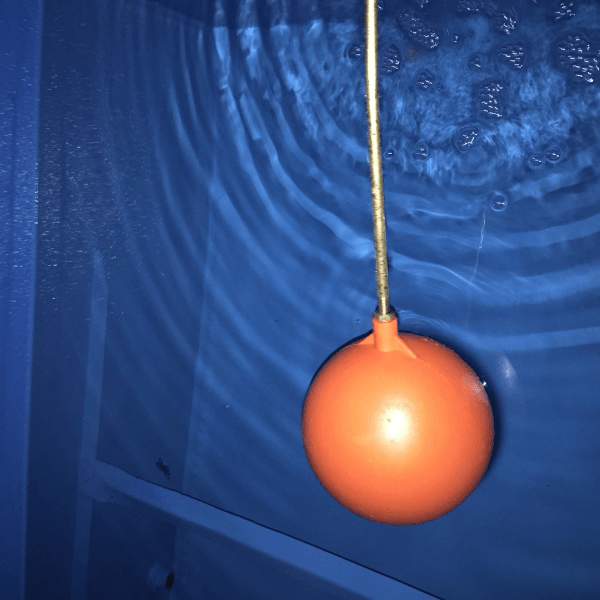

Facilities managers have a legal responsibility for ensuring that water stored and provided on their premises is fit for consumption and not harbouring aquatic micro organisms such as legionella which are harmful to health. Poorly maintained water tanks have the potential to support the growth of such organisms if not properly maintained. Furthermore a correctly installed tank lining will extend the service life of your valuable asset, often for significantly less than the cost of replacement. Water tank relining is the best option.

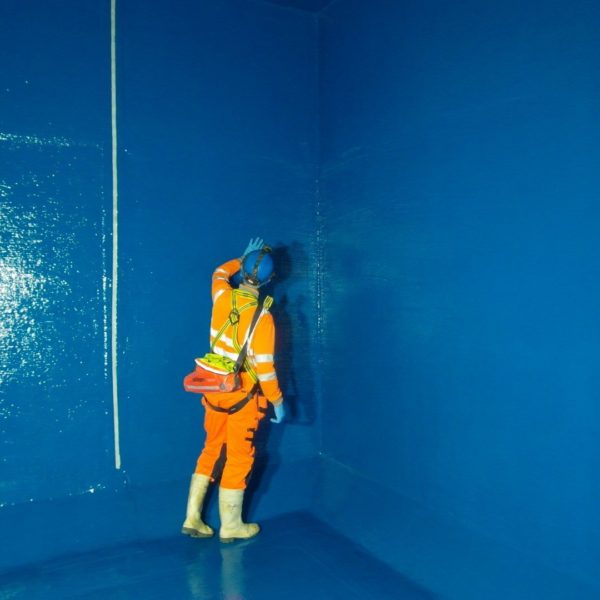

Corroless Eastern have been specifying and applying water tank linings for the past 20 years and have a wealth of experience which you can draw on. From concrete reservoir linings to sectional steel water tanks we have the tank lining you require. Our water tank liners are experienced and trained in applying the whole spectrum of water tank lining systems to ensure that your tank is fit for service.

Any tank lining used for the storage or processing of drinking water must be Regulation 31 approved, if used in the public supply or WRAS approved if used within a consumers premises. Because we apply a variety of materials from a range of manufacturers we can select the best material for the job and can often suggest a choice of specifications to suit your budget.

Our commitment to installing tank linings of the highest quality allows us to offer meaningful warranties on our works giving you piece of mind on your investment.

Steel Water Tanks Relining

If left unprotected in an immersion environment steel will quickly corrode creating an environment which will support aquatic micro organisms. Degradation of the structure will also rapidly occur eventually leading to perforations in the tank structure meaning that it is no longer water containing.

As with all coating application correct surface preparation is essential, however with steel water tanks removing rust and scale which is present is essential to prevent the corrosion of the tank under the new lining. We are able to offer the full spectrum of preparation when lining a steel tank from Ultra high pressure water jetting, abrasive blasting and mechanical/manual preparation. Failure to properly prepare the steel will result in premature failure of the tank lining.

The tank lining specification must be adapted to suit the form of surface preparation which has been used. Surface tolerant coatings/primers must be used where only hand preparation is available as they are specifically designed to control the corrosion. Whilst abrasive blasting is widely regarded as the best form surface preparation available it is not always possible or cost effective given the often challenging locations in which water tanks are often located.

To ensure that our steel tank linings are conducted to the highest quality we employ our own in house ICORR (http://www.icorr.org/) paint inspector and our tank liners are trained under the ICATS scheme.

Glass Reinforced Plastic (GRP) Water Tanks

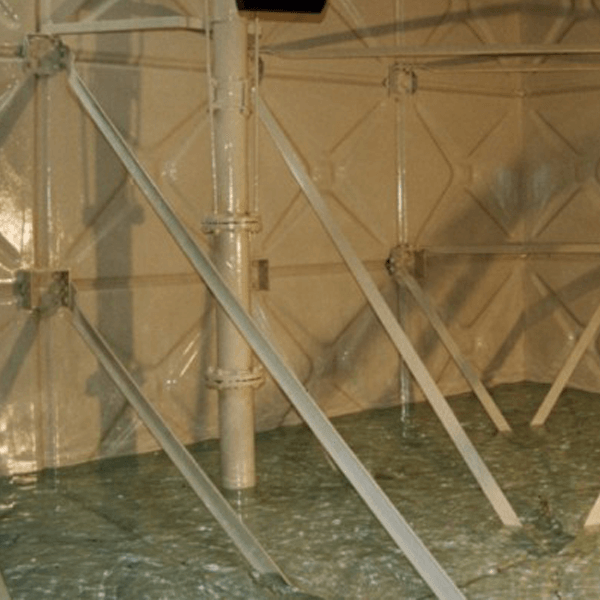

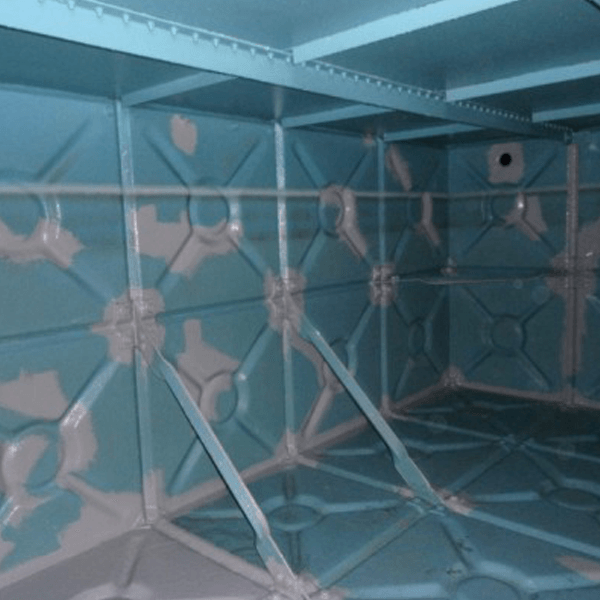

Many facility managers and building owners often incorrectly assume that a GRP tank will be maintenance free due to not experiencing corrosion in the way that steel does. Unfortunately the refurbishment of GRP water tanks forms a significant part of our work, either through leaking or degradation of the panels themselves.

Due to the sectional nature of these tanks movement often occurs between the panel joints during cyclic emptying and filling which along with degradation of the gasket material used between the panels can result in water egress from the tanks.

The panels themselves can also degrade over time and we have witnessed cracking of the panels themselves at the extreme. On the smaller but as critical scale the panels themselves can become porous over time through the degradation of the tank surface resulting in creation of blisters and porosity which can harbour aquatic microorganisms such as legionella.

In addition to the above problems the fixings which are used to hold the panels together often corroded resulting in staining and contamination of the water. We can solve all of these problems through the correct specification and application of an appropriate tank lining.

Relining Concrete Water Tanks

Concrete has been used for the storage and retention of water extensively, especially in the public supply. Whilst the material has a long service life it can suffer from attack as a result of process chemicals and erosion as a result of water flows.

Concrete tanks can be protected and their service life extended by the application of a protective tank lining. We would typically specify a flexible polyurethane or polyurea tank lining due to their ability to fill cracks.

Concrete can often be porous in nature with blow holes and imperfections present in the surface being coated. It is essential that these are correctly filled prior to the application of the tank lining as it is not possible to fill these with the lining alone. Failure to do so will result in breaks in the lining which could not only result in premature failure but also provide a habitat for aquatic microorganisms. Many of our competitors will omit this crucial stage of the lining process due to their lack of understanding of correct tank lining methodology.

As with steel tanks once installed all of our concrete tank linings are spark tested to ensure the lining is free from pin holing and imperfections to ensure the longest possible service life from the tank lining.